CPP & BOPP: PP Film Powerhouses

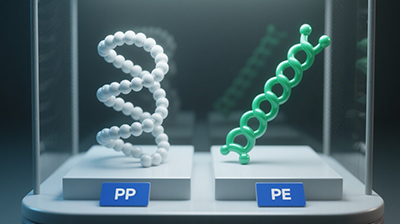

Polypropylene (PP) film is one of the leading materials today. It is used for flexible packaging as well as industrial applications. Two important forms of polypropylene film include:

1. Cast Polypropylene Film (CPP)

Manufacturing Process:

CPP is produced by cast extrusion process, where molten PP is extruded through a flat die onto a chilled roll, forming a film in one go without mechanical stretching. This rapid cooling process results in minimal molecular orientation of the film, which is different from oriented films such as BOPP.

Key Features:

Tear and Puncture Resistance: CPP has excellent impact and puncture resistance, making it suitable for packaging heavy or irregularly shaped items.

Transparency and Clarity: High optical clarity allows for clear product visibility, which is critical for food packaging and consumer goods.

Heat Resistance: Unlike some other polyolefins, CPP maintains structural integrity at high temperatures, making it suitable for hot-fill packaging and retort processes.

Barrier Properties: Although CPP has good moisture and aroma protection properties, its higher water vapor permeability compared to BOPP limits its use in ultra-long-term storage applications.

Sealing: Lower sealing temperatures enable efficient production on high-speed packaging lines, a key advantage in the food and pharmaceutical industries.

Types and applications:

Standard CPP: Basic packaging for snacks, frozen foods, and produce.

Heat-seal CPP: Coated with a heat-seal layer for applications that require sealing, such as cereal bags and stand-up pouches.

Metallized chlorinated polypropylene (MCPP): A thin layer of metal (e.g., aluminum) is deposited through a vacuum metallization process to enhance its barrier properties to oxygen, moisture, and UV. MCPP is widely used in high-end food packaging (e.g., coffee, candy) and pharmaceutical blister packaging.

CPP composite films: Composited with other films (e.g., polyethylene, polyester) to form a stronger and more functional multilayer structure for retort pouches and pet food packaging.

2. Biaxially oriented polypropylene film (BOPP)

Production process:

BOPP is produced using a two-step stretching process: the molten PP is first cast into a thick amorphous film, and then mechanically stretched in the longitudinal direction (machine direction, MD) and transverse direction (transverse direction, TD) at a temperature close to its glass transition temperature. This directional arrangement of molecular chains significantly improves the mechanical properties of the film.

Key features:

Tensile strength and stiffness: Compared with CPP, the tensile strength of BOPP after stretching can be increased by 3-5 times, making it suitable for load-bearing applications.

Punch and flex crack resistance: It can maintain integrity under repeated bending, which is critical for applications such as labels and flexible packaging that are subject to mechanical stress.

Optical properties: BOPP has excellent gloss and transparency, which is generally better than CPP and is the first choice for high-quality printing and lamination.

Barrier properties: Low gas (e.g. oxygen) and moisture permeability, extending the shelf life of dry goods packaging (e.g. rice, noodles).

Surface treatment: Easy to print and coat, can present bright patterns and add other functions (e.g. antistatic agents, slip agents).

Types and applications:

Glossy BOPP: Standard, high gloss, used for snack bags, baked goods packaging and book lamination.

Matte BOPP: Anti-reflective treatment, often used for high-end packaging (e.g. high-end cosmetics, stationery) and matte labels.

Aluminum-coated BOPP (MBOPP): Similar to MCPP, but has better barrier properties due to molecular orientation. Used for shelf-stable products (e.g. potato chips, powdered beverages) and cigarette packaging.

Heat-shrinkable BOPP: Heat-shrinks, ideal for shrink wrap, bottle labels and tamper-evident seals.

Electrical BOPP: High dielectric strength makes it suitable for capacitor insulation in electronics and power transmission systems.

Our platform connects hundreds of verified Chinese chemical suppliers with buyers worldwide, promoting transparent transactions, better business opportunities, and high-value partnerships. Whether you are looking for bulk commodities, specialty chemicals, or customized procurement services, TDD-Global is trustworthy to be your fist choice.